The Transformative Impact of LeachWELL 60X on Bottle Roll Assays in Gold Mining

Revolutionizing Bottle Roll Assays: The Impact of LeachWELL 60X on Gold Leaching Efficiency

Published May 20, 2025

In the world of gold mining and mineral processing, accurate and efficient assaying methods are critical. They determine the feasibility of mining projects, guide operational decisions, and influence profitability. One product that has significantly transformed the landscape of gold assaying is LeachWELL 60X, especially when used in bottle rolls. This article delves into the use of LeachWELL 60X in bottle roll assays and explores how it has become synonymous with this essential method.

Understanding Bottle Roll Assays

Bottle roll assays are a standard laboratory technique used to determine both

the total gold content and the recoverable gold content of ore samples This method simulates the

leaching process on a smaller scale, providing valuable data on the potential recovery of gold.

The dissolution of gold is described by the chemical reaction known as the "Elsner

equation":

4 Au + 8 NaCN + O2 + 2 H2O → 4 Na[Au(CN)2] + 4 NaOH

This can be further elucidated as comprising two distinct reactions, which stem from the generation

and consumption of peroxide.

2Au + 4NaCN +O2 =>2NaAu(CN)2+ 2NaOH + H2O2 ….(1)

2Au + 4NaCN +H2O2 => 2NaAu(CN)2+ 2NaOH .…(2)

The process typically involves:

- Placing a Measured Quantity of Ore in a Bottle: The ore is crushed and finely ground to increase the surface area for leaching. A precisely measured amount of this ground ore is placed into a laboratory bottle.

- Adding a Leaching Solution: Typically, a cyanide solution is used to dissolve the gold from the ore. The leaching solution must be carefully prepared to ensure the correct concentration and pH (pH reagents such as lime and caustic can also be added if required)

- Continuous Rolling: The bottle is rolled continuously for a specified period, ensuring thorough mixing and contact between the ore and the leaching solution. This step mimics the agitation and mixing that occurs in full-scale leaching operations.

The primary goal of a bottle roll assay is to evaluate how much gold can be extracted from the ore under controlled conditions. This information is vital for designing and optimizing full-scale leaching operations. The data obtained can help determine the potential yield of a mining project, influencing both economic viability and operational strategies.

Crucially, should the leached pulp residue undergo assay procedures such as Fire Assay or Aqua Regia Digest, it enables the determination of a comprehensive total metal value for the sample.

The results of a bottle roll test program can significantly influence the viability of a project, potentially determining its success or failure.

Time as a Factor

The time required for cyanide to leach gold from a sample depends on several factors, including ore mineralogy, liberation size, temperature, solids percentage, and oxygen concentration. Typically, a bottle roll assay is conducted over 24 to 48 hours to ensure maximum extraction is achieved. Regular sampling throughout the test allows for the development of an extraction profile, providing valuable insights into the leaching process.

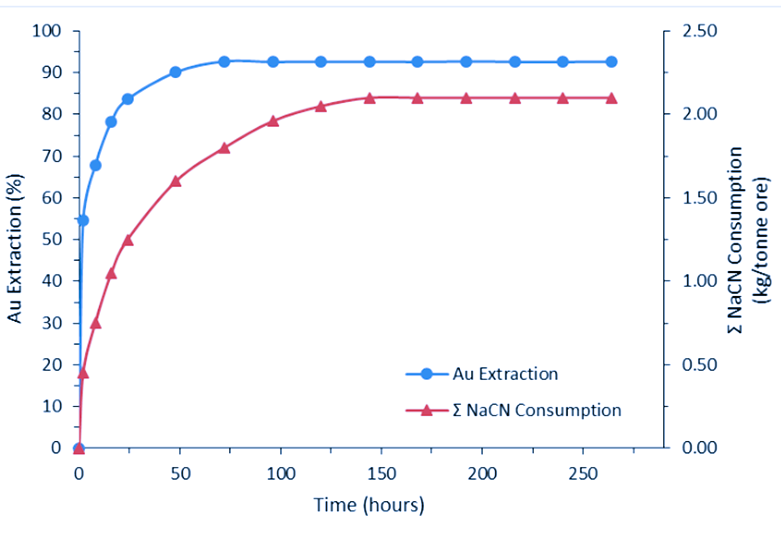

Typically, as illustrated in the image above, the leaching process will eventually reach a point of diminishing returns, where extraction rates plateau and additional leach time does not result in the recovery of significant additional amounts of gold. This is crucial for several reasons:

- Pre-feasibility and Feasibility Studies: Understanding the time when the leaching plateaus assists in determining the appropriate process residence time, which dictates tankage volumes and flow rates necessary for optimal operation.

- Operational Efficiency: For operating mines requiring an understanding of the total recoverable gold percentage, continuing the leach test beyond the plateau wastes time and resources. Leaching past this point does not improve recovery rates and incurs unnecessary costs.

The Role of LeachWELL 60X

LeachWELL 60X, a proprietary product developed by

Mineral Process Control

(MPC) Pty Ltd is a powerful accelerant designed to enhance the leaching process for both

gold and silver. LeachWELL enhances the leaching process in several ways to increase reaction

kinetics. It catalyzes the Au/CN reaction (the Elsner equation), accelerating the dissolution of

gold. Additionally, LeachWELL reduces cyanide consumption caused by ore mineralogy (most typically

due to contained sulphides), thereby maintaining higher free cyanide concentrations for more

effective gold dissolution. The combined effect is to accelerate the leaching of gold by cyanide by

up to 60 times, resulting in maximum leaching occurring after 1 to 2 hours, down from 48 hours.

When used in bottle roll assays, LeachWELL 60X offers several significant

advantages:

Enhanced Leaching Efficiency

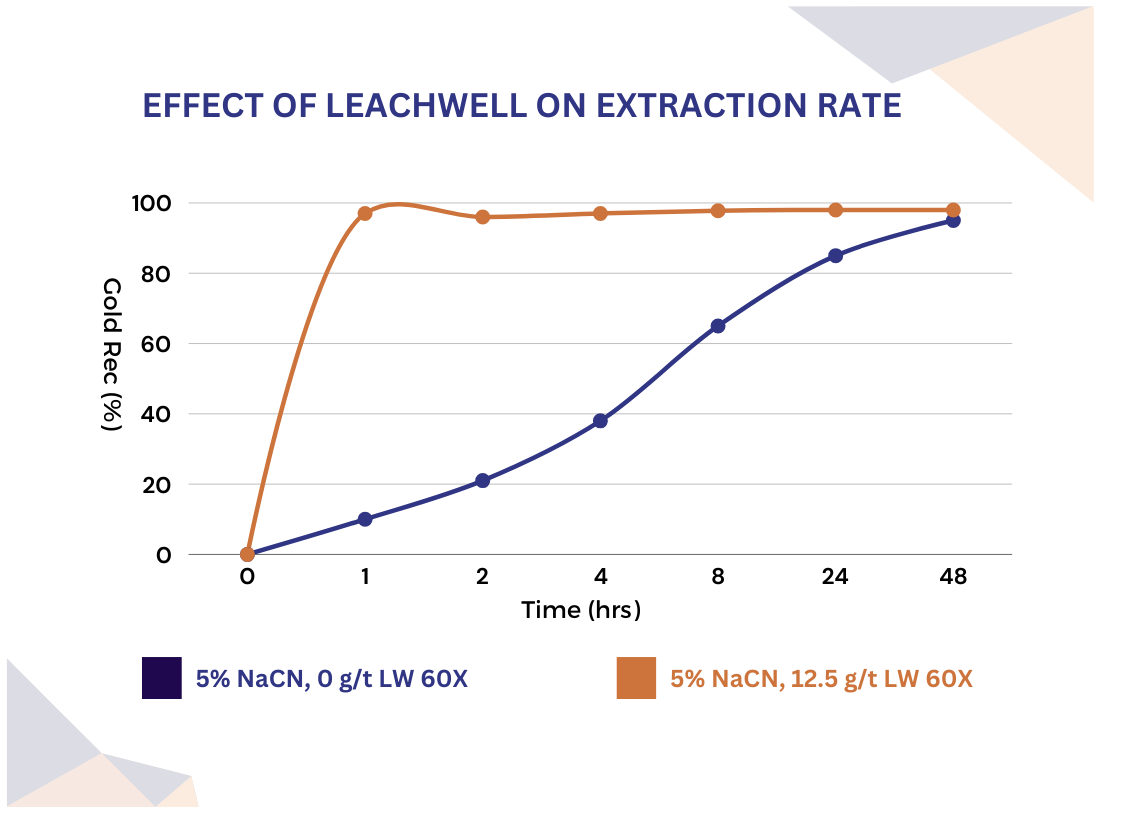

One of the most notable attributes of LeachWELL 60X is its capability to expedite the gold leaching process. The kinetics of reactions 1 and 2 above can be slow and susceptible to inhibitors such as temperature variations, liberation size, mineral particle size, and sulphide cyanide consumption. Liberation and particle size aside, for a sufficiently ground sample, adding LeachWELL 60X will increase the reaction kinetics.The leach recovery plot below illustrates the percentage of gold recovery from duplicate samples, both with and without the addition of LeachWELL 60X. Under standard cyanide leach conditions, gold recovery shows a steady increase over 48 hours, with evidence suggesting the onset of a recovery plateau beyond this period. However, the addition of LeachWELL 60X significantly enhances reaction kinetics, achieving maximum recovery within 1 to 2 hours.

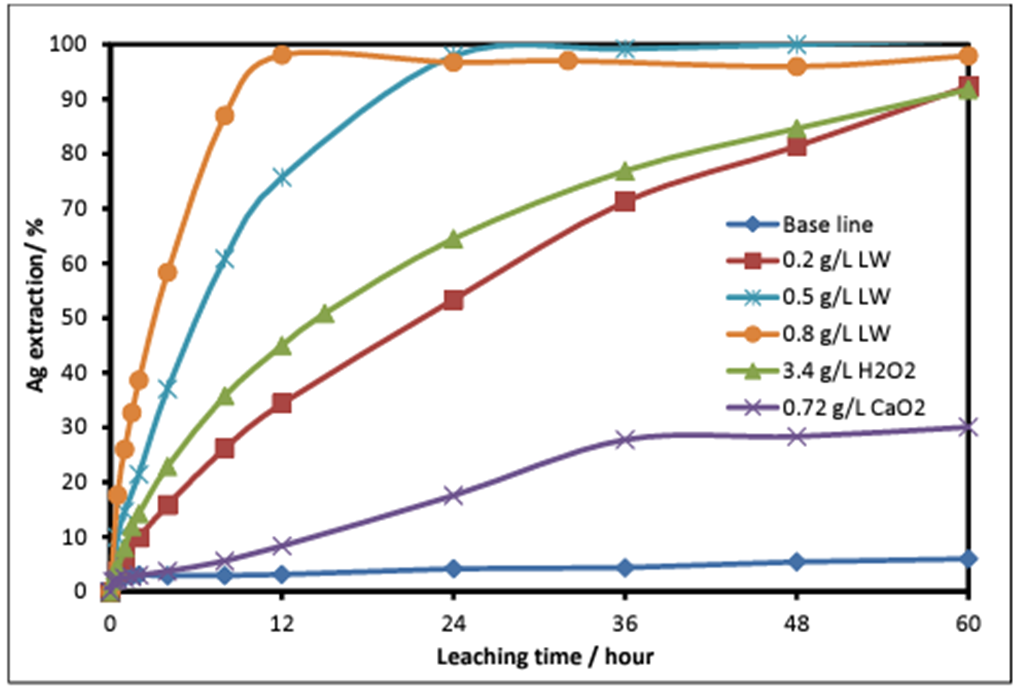

LeachWELL 60X can also be effectively utilized to accelerate the cyanide leaching process for silver, exhibiting similar enhancements in reaction kinetics to those observed with gold. In a AgS system, the application of LeachWELL 60X has demonstrated superiority over the mere increase of peroxide and lime, not only in augmenting the total silver recovery but also in significantly enhancing the recovery rate.

Shorter Assay Times

Time is a critical factor in the mining industry, and assay processes are no exception. Many decisions within the mining cycle rely on the results of assays and test work. Consequently, the turnaround time for these results often becomes a rate-determining step. Traditional bottle roll assays can take up to 48 hours or more to achieve satisfactory results. Reducing the turnaround time for results from a bottle roll test offers significant and tangible benefits for explorers, miners, processors, and laboratory managers.As demonstrated, the use of LeachWELL 60X significantly accelerates the leaching process, providing reliable data within a much shorter timeframe. This reduction in assay time facilitates quicker decision-making and project assessments, enabling mining operations to be more agile and responsive to changing conditions. Faster assay results empower companies to proceed with exploration, development, and processing activities with greater confidence and efficiency.

Consistent and Reproducible Results

The formulation of LeachWELL 60X ensures consistent performance across different ore types and conditions. By ensuring maximum metal recoveries in a short period, LeachWELL 60X eliminates any uncertainty regarding the completeness of the leaching process. Additionally, its positive impact on sulphide mineralogy ensures that excessive amounts of cyanide are not necessary for the complete leaching of gold and silver.This reliability is crucial for maintaining the integrity of assay results, allowing mining companies to make informed decisions based on trustworthy data.

Consistency in assay results is essential for evaluating the economic feasibility of mining projects, planning extraction strategies, and optimizing processing techniques. With LeachWELL 60X, laboratories can achieve reproducible results, ensuring that the data they provide is accurate and dependable.

Sample Size

The precision of assay results in bottle roll tests is significantly influenced by the size of the sample used. When larger sample sizes are employed, typically ranging from 500 grams to 2 kilograms, the precision of the assay tends to increase. This is primarily due to the larger sample size providing a more representative cross-section of the material being tested, reducing the effects of sampling variability. With a larger sample size, any variations or heterogeneities within the sample are more likely to be averaged out, leading to more reliable and consistent assay results.Moreover, the use of larger sample sizes allows for a more thorough extraction of metals from the sample material during the leaching process. This is particularly important when dealing with heterogeneous or complex ore samples, where smaller sample sizes may not adequately capture the variability in metal content. By using larger sample sizes, a greater proportion of the available metal content is extracted, leading to more accurate assay results.

Additionally, the incorporation of leachWELL 60X technology further enhances the precision and efficiency of bottle roll tests. By utilizing leachWELL 60X in combination with larger sample sizes, the leaching process becomes more effective and efficient, resulting in faster and more precise assay results.

Synonymous with Assay Methodology

Over the years, the use of LeachWELL 60X in bottle roll assays has become so prevalent that it is now virtually synonymous with the assay method itself. A review of gold mining and exploration company disclosures frequently references the "LeachWELL Assay" as a pivotal tool for assessing potential metal recoveries in their projects.This widespread adoption is a testament to the product's effectiveness and the confidence it has garnered within the industry. Mining companies, laboratories, processors and geologists have come to rely on LeachWELL 60X for its proven ability to deliver accurate and timely assay results. The product's reputation for reliability and efficiency has made it a standard tool in gold assaying, cementing its place as an essential component of modern mining practices. While other products have attempted to replicate LeachWELL, as the originator of the original accelerant no other supplier can equal MPC's expertise and technical mastery in the application and underlying chemistry of its formulation.

Detailed Case Studies and Real-World Applications

Case Study 1: Evaluating the Effectiveness of LeachWELL in Re-analysis of Drilling Samples at a West African Gold Project Introduction

A gold exploration company in West Africa re-analyzed drilling samples from a permit area adjacent to its main gold project in southern Mali. The initial assays were conducted using a 50g fire assay method. To obtain more accurate and representative results, the company employed a 2kg LeachWELL bottle roll analysis combined with a 50g fire assay on the residues. This case study assesses the effectiveness of the LeachWELL method in improving assay accuracy and reliability.Background

The project represents a key exploration focus for the company, with initial drilling conducted in the fourth quarter of 2020. The first-pass results, derived from the 50g fire assay, were suitable for quick screening but insufficient for detailed resource estimation. Therefore, a more comprehensive method was required to fully understand the deposit's potential.Methodology

To enhance assay quality, the company re-analyzed 355 sample intervals from 19 significant intercepts using the LeachWELL method:- Sample Preparation: Samples were re-split into 4kg sub-samples.

- LeachWELL Bottle Roll: Each 2kg sub-sample underwent LeachWELL bottle roll analysis.

- Fire Assay on Residue: A 50g fire assay with Atomic Absorption Spectroscopy (AAS) finish was conducted on the dried residue to determine any remaining gold.

Results

The re-analysis using the LeachWELL method yielded significantly improved results in terms of both intercept widths and grades compared to the initial 50g fire assay:- Hole Example #1:

i) Initial: 5m @ 3.75 g/t Au from 84m

ii)Re-analysis: 5m @ 6.14 g/t Au from 84m - Hole Example #2:

i) Initial: 13m @ 1.61 g/t Au from 55m

ii) Re-analysis: 13m @ 1.87 g/t Au from 55m - Hole Example #3:

i) Initial: 3m @ 2.08 g/t Au from 24m and 12m @ 0.75 g/t Au from 33m

ii) Re-analysis: 13m @ 1.20 g/t Au from 15m and 13m @ 1.20 g/t Au from 33m

Discussion

The use of the 2kg LeachWELL bottle roll analysis, complemented by a 50g fire assay on the tail, proved superior for assaying deeply weathered, sediment-hosted oxide gold deposits in southern Mali. The improved precision and higher grades indicated that the LeachWELL method more accurately reflects the true gold content of the samples.These enhanced results provide a better understanding of the gold deposits and significantly increase the potential resource base of the flagship gold project. With considerable surface mineralization yet to be drilled, the re-analysis highlights the importance of using more representative assay methods in resource estimation and exploration.

Conclusion

This case study illustrates the effectiveness of the LeachWELL method in re-analyzing drilling samples, offering more accurate and reliable results than the traditional 50g fire assay. The significant improvements in assay precision and gold grades underscore the project's potential to contribute to resource expansion at the flagship gold project. This approach sets a new standard for future assay methods in similar geological settings, emphasizing the necessity of comprehensive and representative sampling techniques in gold exploration.Case Study 2: Effectiveness of LeachWELL in Grade Control Drilling at a British Columbia Gold Project Introduction

A gold exploration firm implemented a grade control drilling program to increase confidence in the elevated gold grades within the near-surface mineralization of their planned high-grade starter pit in British Columbia, Canada. Initially, assays were conducted using a 50g fire assay method; however, the firm later transitioned to a 1,000g LeachWELL bottle roll assay to improve accuracy and reliability. This case study evaluates the effectiveness of the LeachWELL method in enhancing assay precision and understanding the orebody's leachability.Background

The grade control drilling program aimed to confirm and optimize the high-grade ore targeted for the first year of operations, as outlined in a 2020 Pre-Feasibility Study. This extensive reverse circulation (RC) drilling program sought to refine the orebody model, reduce dilution, and enhance mine planning.Methodology

The program consisted of 561 RC holes, totaling 33,216 meters, conducted between November 2020 and March 2021. The objective was to increase drill density from 50x50 meters to 12.5x12.5 meters, significantly boosting data volume compared to previous exploration efforts. The primary goals were to:- Optimize grade selectivity and mine scheduling.

- Accurately delineate ore and waste boundaries to mitigate dilution.

- Optimize drill and blast designs.

- Reduce grade variability through larger sample sizes.

Assay Methodology

The LeachWELL assay method was selected to increase the sample size from the standard 50g to a 1,000g sample, reducing variability and enhancing repeatability. This method offers a more comprehensive understanding of ore leachability, which is crucial for process design. Key steps included:- Sample Preparation: Drill cuttings were collected at 3m intervals, split into approximately 3kg samples using a Jones riffle splitter, and securely stored before shipping.

- Laboratory Analysis: Conducted by a certified geochemical laboratory, involving drying, crushing, and pulverizing samples to 75% passing 75 µm. Gold and silver analyses were performed using a 5-hour LeachWELL method with an inductively coupled plasma mass spectrometry (ICP-MS) finish.

- Residue Analysis: A 50g fire assay on filter-pressed and dried residues determined any remaining gold and silver.

The LeachWELLTM method demonstrated excellent repeatability and significantly improved assay precision:

- Gold Recovery: 96.5%

- Silver Recovery: 69.3%

Continuity of Mineralization

The program validated the continuity of high-grade mineralization, which is crucial for the early stages of mine life and for reducing operational risks. The improved data quality enhances short-term mine planning, optimizing ore processing, and reducing the strip ratio at the start of operations.The drill sampling process involved collecting reverse circulation drill cuttings and splitting samples into manageable sizes. Chain-of-custody procedures ensured sample integrity from collection to laboratory analysis. The representativeness of the LeachWELL technique was verified through comparisons with 50g fire assay results and existing drill hole data. Quality assurance and quality control (QA/QC) measures included inserting blank and duplicate samples into the sample stream at a rate of approximately 14%.

Discussion

The transition to the 1,000g LeachWELL bottle roll method proved highly effective in assaying this project's gold deposits. The method's enhanced precision and higher recovery rates underscore its superiority over traditional 50g fire assays. These improvements provide a more accurate understanding of the orebody, which is essential for resource estimation and mine planning.Conclusion

This case study highlights the exceptional effectiveness of the LeachWELL method in grade control drilling, showcasing its ability to deliver more reliable and accurate assay results compared to traditional methods. The substantial improvements in assay precision and gold recovery underscore the method's superiority, demonstrating its capacity to reveal the true potential of the project's resources from the very beginning of mine life. Additionally, the rapid turnaround time of just one hour further enhances its applicability, allowing for quicker decision-making and more efficient operations. The high precision, recovery rates, and speed achieved with the LeachWELL method establish a new benchmark for assay practices in similar geological settings. This underscores the critical importance of comprehensive and representative sampling techniques in gold exploration, solidifying the LeachWELL method's superiority and practicality in grade control scenarios.Summary

In the ever-evolving landscape of gold mining and mineral processing, the significance of accurate and efficient assaying methods cannot be overstated. This article has elucidated the pivotal role of LeachWELL 60X in revolutionizing gold assaying, particularly in bottle roll assays. By enhancing reaction kinetics, reducing assay times, ensuring consistent results, and accommodating larger sample sizes, LeachWELL 60X has become synonymous with assay methodology itself. Through detailed case studies from West Africa to British Columbia, the effectiveness of LeachWELL in improving assay accuracy and reliability has been demonstrated, setting a new standard for assay practices in the industry. The widespread adoption of LeachWELL underscores its indispensability, affirming its position as an essential component of modern mining practices and a catalyst for informed decision-making and efficient operations in gold exploration and processing.Sources:

Source 1: Leaching profile of a relatively free-milling Au-ore by bottle roll testing on 150 µm feed. Source: Cetin, Mahir & Altun, N. & Atalay, M.U. & Buyuktanır, K.. (2017). Bottle Roll Testing for Cyanidation of Gold Ores: Problems related to Standardized Procedures on Difficult-to-Process Ores. 10.11159/mmme17.148.Source 2: MPC Customer data.

Source 3. Hao.J, (2014), Comparative study of Auxillary Oxidants in the Cyanidation of Silver Sulfide. Central South University, China, 2010